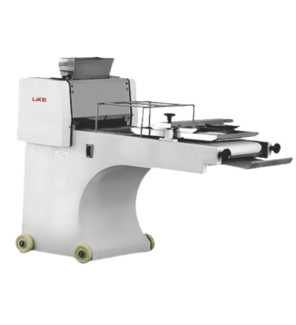

Model Name: Toas Moulder

Model No:

A toast moulder, also known as a bread moulder or bread rolling machine, is a specialized kitchen or bakery appliance designed for shaping and preparing bread dough for baking. It plays a crucial role in the production of various types of bread, including loaves, baguettes, and other baked goods. Here's a detailed description of a typical toast moulder:

-

Construction and Design:

- A toast moulder typically consists of a sturdy metal frame with various components made of stainless steel or food-grade materials.

- It has a conveyor belt system that allows the bread dough to pass through the machine.

- The machine usually includes adjustable rollers and pressure plates, which can be fine-tuned to control the thickness and shape of the dough.

-

Operation:

- To use a toast moulder, a baker or operator places a portion of bread dough onto the input side of the conveyor belt.

- The dough is then gently fed into the machine, where a series of rotating rollers and pressure plates gradually shape and flatten it.

- As the dough passes through, it is compressed and elongated into the desired shape, whether it's a long baguette or a loaf of bread.

-

Adjustability:

- Toast moulders often feature adjustable settings to accommodate different dough sizes, shapes, and recipes.

- Operators can fine-tune parameters such as roller pressure, dough thickness, and conveyor speed to achieve the desired bread shape and texture.

-

Versatility:

- While primarily used for bread production, some toast moulders can handle various types of dough, including pizza dough and pastry dough, making them versatile tools in a bakery or kitchen.

-

Benefits:

- Saves Time: A toast moulder significantly speeds up the bread preparation process compared to manual shaping, making it an essential tool in commercial bakeries with high production demands.

- Consistency: It ensures uniformity in the size and shape of bread, resulting in more consistent baking and presentation.

- Labor Efficiency: Reduces the need for skilled manual labor in shaping dough, allowing bakers to focus on other aspects of production.

- Improved Texture: Properly moulded dough can lead to a better texture and crumb structure in the finished bread.

-

Maintenance:

- Regular cleaning and maintenance are essential to keep the toast moulder in optimal working condition. This includes cleaning rollers, belts, and other components.

- Voltage: 220-380V

- Power: 1.1kW/h

- Dimension (L*W*H): 980 x 1090 x 1580 mm

- Net Weight: 220 KGS

- Capacity: --

- Temperature: --

- Speed: --

- Flour Capacity: --