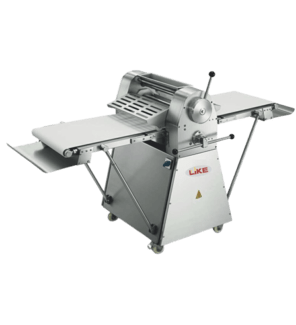

Model Name: Dough Sheeter 650

Model No:

A 650 Dough Sheeter is a specialized piece of bakery equipment designed for rolling and flattening dough to a consistent thickness. These machines are commonly used in bakeries, pastry shops, and food production facilities to streamline the dough preparation process. Here's a detailed description of a 650 Dough Sheeter:

Design and Size:

- A 650 Dough Sheeter typically features a robust and compact design, making it suitable for use in commercial kitchens with limited space.

- It consists of a motorized base with a pair of parallel, counter-rotating rollers mounted on top.

Roller Width:

- The number "650" in the name often refers to the width of the rollers in millimeters, which is approximately 650 mm (25.6 inches).

- The width of the rollers determines the maximum width of dough that can be processed.

Rolling Mechanism:

- The dough sheeter uses a rolling mechanism that passes the dough between the two counter-rotating rollers.

- As the dough passes through, it is gradually flattened and rolled to the desired thickness.

Adjustable Thickness:

- 650 Dough Sheeters typically offer adjustable thickness settings, allowing users to control the thickness of the rolled dough.

- These settings are often easy to adjust using knobs or levers, allowing for precise thickness control.

Conveyor Belt:

- Many dough sheeters feature a conveyor belt system that helps guide the dough through the rollers and ensures an even and consistent thickness.

- The conveyor belt can be adjusted to accommodate different dough sizes and thicknesses.

Safety Features:

- Safety features such as emergency stop buttons and safety guards are commonly integrated to ensure the safety of operators during operation.

Durable Construction:

- These machines are built with durability in mind, often featuring a metal housing and stainless steel rollers for long-lasting performance.

Applications:

- A 650 Dough Sheeter is used primarily for rolling and flattening dough for a wide range of baked goods, including bread, pizza, pastry, croissants, and more.

- It is an essential tool in bakeries and food production facilities to ensure uniform dough thickness.

Ease of Cleaning:

- Many dough sheeters are designed for ease of cleaning, with removable parts and accessible surfaces.

- Regular cleaning and maintenance are essential to keep the machine in optimal working condition.

Maintenance:

- Routine maintenance, such as cleaning, lubrication of moving parts, and belt adjustments, is crucial to ensure the dough sheeter continues to function optimally.

- Voltage: 220-380V

- Power: 1.10kW/h

- Dimension (L*W*H): 1100 x 3100 x 1100 mm

- Capacity: 6.5 Kg

- Flour Capacity: 6.5 Kg

Model Name: Dough Sheeter 520

Model No:

A 520 Dough Sheeter is a specialized bakery machine used for rolling and flattening dough to a consistent thickness. These machines are commonly found in bakeries, pastry shops, and commercial kitchens where precision in dough preparation is crucial. Here's a detailed description of a 520 Dough Sheeter:

Design and Size:

- A 520 Dough Sheeter is designed with a compact and efficient structure, making it suitable for smaller commercial kitchens and bakeries.

- It typically consists of a motorized base with a pair of parallel, counter-rotating rollers mounted on top.

Roller Width:

- The "520" in the name generally refers to the width of the rollers in millimeters, which is approximately 520 mm (20.5 inches).

- The width of the rollers determines the maximum width of dough that can be processed.

Rolling Mechanism:

- The dough sheeter utilizes a rolling mechanism that passes the dough between the two counter-rotating rollers.

- As the dough is fed through, it is progressively flattened and rolled to achieve the desired thickness.

Adjustable Thickness:

- 520 Dough Sheeters typically come with adjustable thickness settings, allowing users to control the thickness of the rolled dough.

- These settings are often easy to adjust using knobs or levers for precise thickness control.

Conveyor Belt:

- Many dough sheeters feature a conveyor belt system that assists in guiding the dough through the rollers, ensuring even and consistent thickness.

- The conveyor belt can be adjusted to accommodate different dough sizes and thicknesses.

Safety Features:

- Safety features such as emergency stop buttons and safety guards are typically incorporated to ensure the safety of operators during operation.

Durable Construction:

- These machines are constructed with durability in mind, often featuring a metal housing and stainless steel rollers to ensure longevity and withstand heavy use.

Applications:

- A 520 Dough Sheeter is primarily used for rolling and flattening dough to a consistent thickness.

- It is an essential tool in bakeries and commercial kitchens for preparing dough for various baked goods, including bread, pizza, pastry, croissants, and more.

Ease of Cleaning:

- Many dough sheeters are designed for ease of cleaning, with removable parts and accessible surfaces.

- Regular cleaning and maintenance are essential to ensure the machine continues to operate efficiently.

Maintenance:

- Routine maintenance, such as cleaning, lubrication of moving parts, and belt adjustments, is crucial to maintain the dough sheeter's optimal performance.

- Voltage: 220-380V

- Power: 0.55kW/h

- Dimension (L*W*H): 960 x 2700 x 1100 mm

- Capacity: 5.5 Kg

- Flour Capacity: 5.5 Kg